One - Stop Majordomo For Steel Rolling Mills Plant

We mainly provide design, manufacturing, installation and after-sales service for various steel production lines such as wire rod, bar, steel bar, angle steel, pipe, etc.

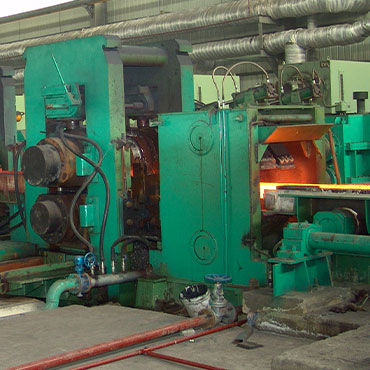

We provide various rolling mills, including small rolling mills, large rolling mills, rough rolling mills, medium rolling mills, etc., as well as finishing mills, which can improve your production capacity and save costs.

We also have all the auxiliary equipment required for hot rolling mills, including 1# shear, 2# shear, 3# shear, double length shear, water washing scale equipment, speed increaser, speed reducer, cylinder system, hydraulic system, etc.

We can also quickly provide spare parts required for rolling mills, such as rollers, bearings, sleeves, guides, universal joint couplings, etc. to meet customer requirements.

One-Stop Construction And Procurement Platform For Steel Rolling Mills Plant

- Steel Rolling Mills

- Rolling mill

- Auxiliary equipment

- Spare parts

What Can Our Equipment Do?

We can provide design and equipment manufacturing of various steel product rolling production lines, including bar rolling mills, wire rolling mills, rebar rolling mills, steel bar rolling mills, plate rolling mills, coil rolling mills, strip steel rolling mills, profiles (angle steel, square steel, I-beam, C-beam, channel steel, etc.), spring steel, various carbon steels, etc.

Project Cases

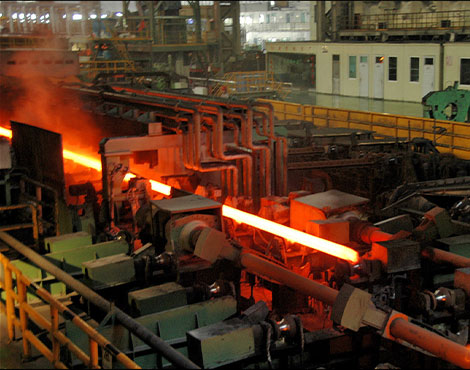

We value every customer and have delivered successful steel mill construction projects worldwide, including completed rolling mills and ongoing steel plant construction. Our extensive experience in steel rolling mill construction and rolling mill project delivery has built deep industry expertise, enabling us to achieve your steel mill engineering goals efficiently.

Professional Metallurgical Equipment Manufacturer.

Hani Steel specializes in steel rolling mill construction and metallurgical equipment manufacturing. We provide complete steel mill construction project services, integrating R&D, steel mill engineering, design, production and sales for rolling mill turnkey projects worldwide.

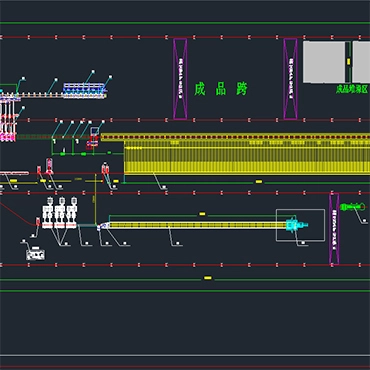

Steel Rolling Mills Design Engineer

Frequently Asked Questions

In order to better meet customer needs, the issues that customers care about are also our concerns.

Don’t worry. When the equipment arrives at the customer’s factory,

our engineers will assist with installation, commissioning and training until the workers can operate it themselves.

We are responsible for container loading and wire fixing. In case of damage, we will send you spare parts.

Our plant has a history of about 25 years in the field of steel rolling equipment service, total solutions for steelmaking and product components.

And our equipment has been exported to East Asia, South Asia, the Middle East, Africa and other regions. There are a large number of successful cases

and good feedback.

Of course, brand licensing is possible. We accept OEM service.

If the parts are in stock, it usually takes 7-14 days. If the parts are not in stock, it will take 30-45 days, depending on the factory capacity.

If it is a customized total solution of the customer, we will negotiate with the customer for delivery time.

Our QC team adheres to TQM to ensure quality. Every step is up to standard.

At the same time, we can take clear photos and videos for you if needed.

Steel Rolling Mill Knowledge

Here you will find steel industry insights, company updates, rolling mill project news, and steel mill construction knowledge.