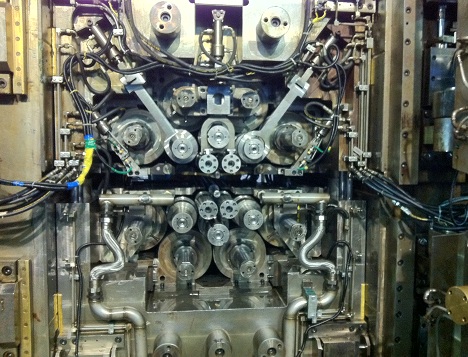

The essential difference between Sendzimir mill (Sendzimir cold rolling mill) and other types of the mill is the direction of rolling force transmission. The rolling force of Sendzimir mill is transferred from the working roll through the intermediate roll to the supporting roll device and eventually to the solid overall stand. This design ensures the support of the work roll in the whole length direction. In this way, the deformation of the roll system is very small, and the thickness deviation can be very accurate in the whole length direction of rolling.

Main Characteristics and Development Level of Sendzimir Mill

The main features of the Sendzimir mill in structure and performance are as follows:

(1) Frame with integral casting (or forging), high stiffness and radial rolling force acting on each section of the frame.

(2) The small diameter of the working roll, the high reduction rate of the pass, up to 60%. Some materials can be rolled into very thin strips without intermediate annealing.

(3)With axial and radial roll shape adjustment, roll diameter size compensation, rolling line adjustment, and other mechanisms, and the use of hydraulic pressure and hydraulic AGC system, the product has a good shape and high dimensional accuracy.

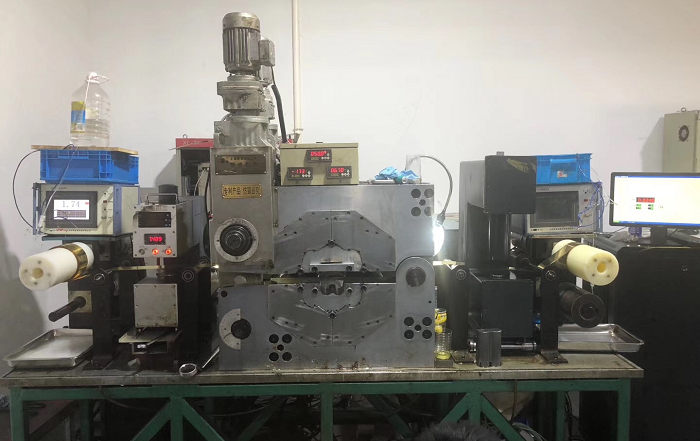

(4) The equipment is light in weight, and the weight of the mill is only one-third of that of the four-high mill of the same specification. Less capital investment is needed.

Sendzimir rolling mill is basically a single stand reversible arrangement, with great flexibility and a wide range of products. However, there are very few Sendzimir mills with a continuous arrangement. For example, Japan Sendzimir Corporation designed a set of 1270 mm four-stand full-continuous 20-roll Sendzimir mill in 1969.

The development level of the Sendzimir mill is as follows:

(1) Maximum width of rolled strip. At present, the widest rolling strip is a ZR22-80 rolling mill in France. The maximum rolling width of soft steel and silicon steel is 2032 mm, and the thickness deviation is 0.005 mm.

(2) Minimum thickness of the rolled strip. The minimum thickness of the rolled strip is related to its width and steel grade. The minimum thickness of rolled silicon steel in the United States is 0.002 mm, its width is 120 mm. The minimum thickness of rolled stainless steel in Japan is 0.127 mm when the width is 1200 mm; the minimum thickness is 0.01 mm when the width is 200 mm, and the thinnest thickness is 0.0018 mm when rolling non-ferrous metals.

(3) Increasing the opening of the rolling mill. In recent years, the French DMS company, together with the American Sendzimir Company, has finally broken the traditional concept of Sendzimir mill as a whole stand and introduced the separate stand Sendzimir mill. The rack is divided into upper and lower parts.

(4) There are also new innovations in shape control. In traditional rolling mills, because of the stiffness of the supporting roll, the control of 1/4 side waves by B and C supporting rolls is limited. So the elastic mandrel supporting roll was invented, which improved the control of 1/4 side wave of rolling mill and the straightness of strip.

(5) The K-ZR 20-high rolling mill manufactured by Hitachi Company of Japan was put into operation in 1991. The mill adopts double AS-U-ROLL roll shape adjusting mechanism, which is set on two pairs of roll sets A, B, C, and D respectively. That is to say, the upper four groups of supporting rolls of the mill can be adjusted. Through the finite element analysis of the pressure distribution between rolls, it can be seen that the pressure distribution between rolls will affect the roll shape during rolling, while the pressure between rolls at the edge of roll system is greater than that at other parts, and the influence on the shape of rolls is greater than that of other parts. Double AS-U-ROLL roll adjusting mechanism can adjust the side support roll. Therefore, double AS-U-ROLL is better than single AS-U-ROLL in shape adjustment and control edge thinning.

(6) Rolling speed. The maximum rolling speed of ZR21-44 rolling mill in the United States is 1067 m/min, and that of ZR21 rolling mill for silicon steel and stainless steel in the United States, Japan, and other countries can reach 800 m/min.