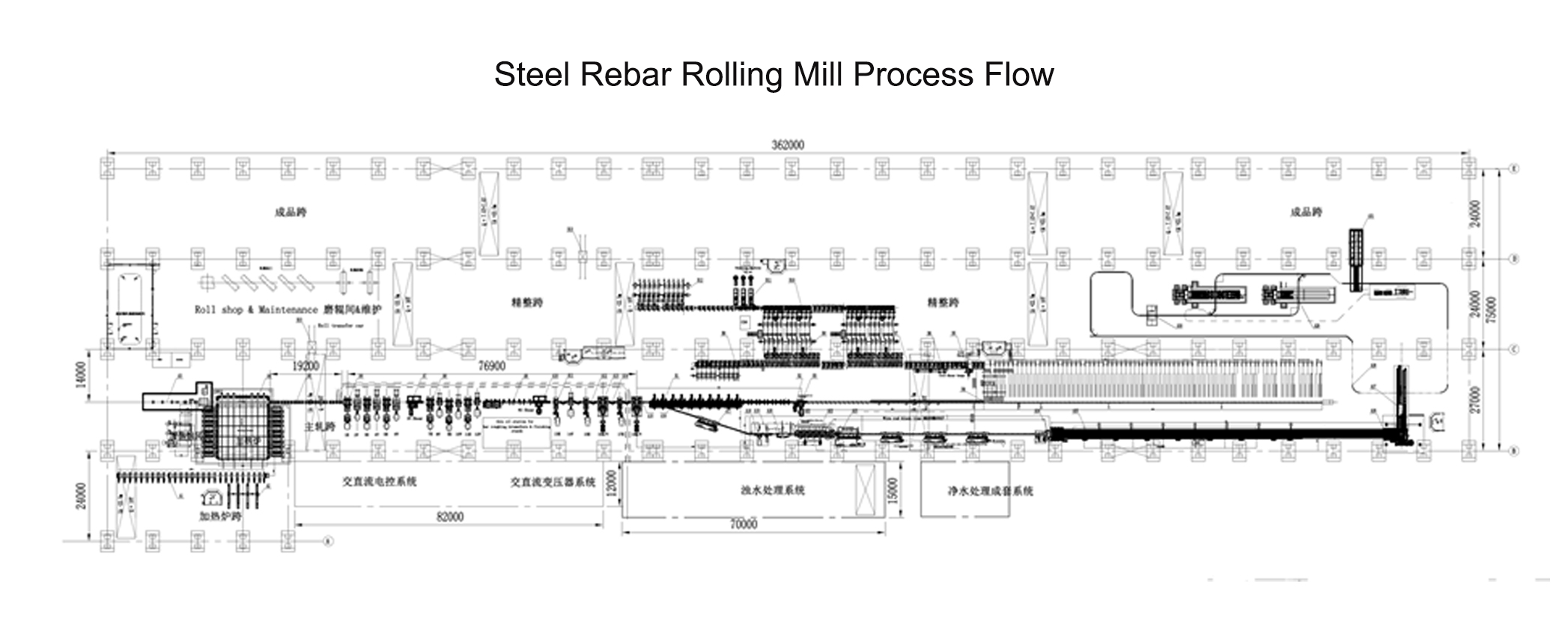

Steel Rebar Rolling Mill Process Flow

The Steel Rebar Rolling Mill Process Flow is as follows:

Steel billet acceptance → heating → rolling → double-length shearing → cooling → shearing → inspection → packaging → measurement → storage

Billet Acceptance

Billet acceptance: The quality of the billet is the key to the quality of the finished product, and it must be checked and accepted.

① The billet acceptance procedures include physical card verification, shape dimension measurement, surface quality inspection, records, etc.

② The acceptance of billets is carried out in accordance with billet technical standards and internal control technical conditions, and unqualified billets are not allowed to enter the furnace.

Billet Heating

Billet heating is an important process in the Steel Rebar Rolling Mill Process Flow.

① The purpose of billet heating

The purpose of billet heating is to improve the plasticity of the steel and reduce the deformation resistance to facilitate rolling; the correct heating process can also eliminate or reduce the internal structural defects of the billet. The heating process of steel is directly related to various technical and economic indicators such as steel quality, rolling mill output, energy consumption, and rolling mill life.

② Three-stage continuous reheating furnace

The so-called three sections are: preheating section, heating section and soaking section.

The function of the preheating section: use the waste heat of the heating flue gas to preheat the billet to save fuel. (Generally preheated to 300~450℃)

The function of the heating section: heat the pre-heated billet to 1150~1250℃. It is the main heating section of the reheating furnace and determines the heating capacity of the furnace.

The function of the soaking section: reduce the temperature difference between the inside and outside of the billet, eliminate the black mark of the water-cooled slide, and stabilize the uniform heating quality.

③ Several common defects in billet heating

A. Overheating

When the billet is heated at a high temperature for a long time, it is very easy to overheat. The overheating phenomenon of the steel billet is mainly manifested in the excessive growth of the grains of the steel structure into a coarse-grained structure, thereby reducing the bonding force between the grains and reducing the plasticity of the steel.

Overheated steel is prone to cracking during rolling, especially at the corners. Cracks will occur on the surface of the steel when it is slightly overheated, which will affect the surface quality and mechanical properties of the steel.

In order to avoid overheating defects, the heating temperature and heating time must be strictly controlled.

B. Overheated

When the billet is heated at a high temperature for a long time, it will become a coarse crystal structure. At the same time, the low melting point non-metallic compound on the grain boundary will be oxidized to destroy the crystal structure and make the steel lose its due strength and plasticity. This phenomenon is called excessive burn. Overfired steel will cause severe cracks during rolling. Therefore, overburning is a more serious heating defect than overheating. Excessive burnt steel cannot be saved except for re-smelting. Ways to avoid overburning: reasonably control the heating temperature and oxidizing atmosphere in the furnace, strictly implement the correct heating system and waiting-to-roll system and avoid excessive temperature.

C. Uneven Temperature

This phenomenon is easy to occur when the billet heating speed is too fast or the output of the rolling mill exceeds the heating capacity. For billets with uneven temperature, the dimensional accuracy of the rolled pieces is difficult to control stably during rolling, and it is easy to cause rolling accidents or equipment accidents. Avoid method: reasonably control the furnace temperature and heating speed; do a good job in the connection of rolling and heating.

F. Oxidation burn loss

The billet is oxidized at room temperature, but the oxidation rate is slower. As the heating temperature increases, the oxidation rate increases. When the billet is heated to 1100-1200°C, it will be oxidized strongly under the action of the furnace gas to form an iron oxide scale. . The generation of iron oxide scale increases heating burn loss, resulting in a decline in the yield index.

Measures to reduce oxidation burn loss: reasonable heating system and correct operation, and control the atmosphere in the furnace.

E. Decarbonization

The phenomenon that the carbon content on the surface of the billet decreases when it is heated is called decarburization. The steels that are easily decarburized are generally high-quality carbon structural steels and alloy steels with higher carbon content. These steels have their special uses. After decarburization, the surface and internal carbon content of the steel are inconsistent, which reduces the strength of the steel and affects its performance. Especially for steels that require high wear resistance, high elasticity, and high toughness, the surface hardness and use performance are greatly reduced due to decarburization, and even waste products are caused. Control method: Strict heating system, reasonable control of furnace temperature, and oxidation atmosphere in the furnace.

Rolling Process

The rolling process is the core of the entire Steel Rebar Rolling Mill Process Flow. Finishing the deformation process through billet rolling becomes the product that users need. The rolling process plays a decisive role in product quality.

The quality of rolled products includes product geometry, dimensional accuracy, internal organization, process mechanical properties, and surface finish. Therefore, the rolling process must formulate corresponding rolling process technical regulations and process management systems in accordance with product technical standards or technical requirements, production product characteristics, and production technical equipment capabilities, as well as production costs and worker labor conditions. To ensure that the quality of rolled products and technical and economic indicators are optimized.

The rolling process of the entire Steel Rebar Rolling Mill Process Flow generally consists of one row (group) or two rows (group) of rough rolling mills, intermediate rolling mills, and finishing rolling mills. Respectively undertake the functions of billet section compression, semi-finished product rolling deformation, and finished product rolling. The pass of the finished rolling mill or the finishing pass is K1, the pass of the front rolling mill is K2, and the pass of the front rolling mill is K3, and so on.

Continuous Rolling Mill and Continuous Rolling Constant?

Continuous rolling mill means that several rolling mill stands are arranged in a row according to the rolling direction, and the rolling pieces are rolled and deformed in several rolling mills at the same time. The rolling speed of each stand increases with the increase of the length of the rolling pieces, and keeps the metal in the rolling method in which the flow rate per second in each rolling mill is equal or has a slight stacking steel relationship is called a continuous rolling mill. Continuous rolling mills have high mechanization, automation, rolling speed, and rolling precision, so the labor productivity is high and the product quality is good. It is the direction of the transformation and new construction of bar and wire rolling mills. The rolling that keeps the rolled pieces passing through the rolling mills in the same volume per unit time is called continuous rolling.

Continuous rolling constant = F1D1N1 = F2D2N2 = F3D3N3 = FnDnNn

Where: F—cross-sectional area of rolled piece mm2

D—Working diameter of roll mm

N—roll revolution (1/min)

Finishing

① Steel Cooling

The cooling bed is the main cooling equipment for rolled bar products. The cooling roller table is the main cooling equipment for wire products. The function of the cooling bed and the cooling roller table is to cool the high temperature rolling stock above 800℃ to below 150-100℃, so as to restore the inherent physical properties of the steel and facilitate the guarantee of the cutting quality and the subsequent process operations.

Cooling method According to the chemical composition, organizational state, use purpose, and possible defects of the steel after cooling, the following cooling methods are determined:

Natural Air Cooling

Natural air cooling is a commonly used cooling method for carbon structural steel, low-alloy structural steel, high-quality carbon structural steel, and austenitic stainless steel. This cooling method generally does not affect the physical properties of the steel.

Forced Rapid Cooling

Forced rapid cooling generally uses air blowing, spraying, water spraying, etc. The process feature is to quickly cool the steel to a certain temperature within a certain period of time before performing natural cooling. This cooling method can generally change the internal structure of the steel and affect the physical properties of the steel. Such as improving the mechanical properties of ordinary wire rods; eliminating steel mesh carbides, etc.

Control Slow Cooling

Steel grades with strong stress sensitivity after cooling are generally cooled by controlled slow cooling, such as high-speed tool steel, martensitic stainless steel, high-alloy tool steel, and high-alloy structural steel. This cooling method can prevent the steel structure from changing and stress concentration from causing cracks.

② Steel Cutting

The purpose of steel cutting: cut off the parts that affect the use (defects) of the steel, such as the head and tail of the steel; cut to the length required by the user.

Steel cutting equipment is divided into cold shear and hot shear. Hot shears are often used for heading, tailing or double-length cutting of semi-finished products; cold shears are often used for heading, tailing or cutting of finished steel products.

System heating furnace temperature and semi-finished product size; strictly adjust the guide and guard device; improve the pre-installation accuracy of the rolling mill; timing and quantitative reverse pass.

③ Steel Inspection

Steel inspection is a key process to ensure that product quality meets product technical standards and technical conditions.

Product inspection usually includes:

Steel shape size, surface quality, cut-to-length length, weight deviation, process performance, mechanical performance, etc. Steel products that do not meet the product quality standards must be sorted out and sorted for disposal.

Common defects on the surface of products and preventive measures. Rod and wire products are generally required to be free of defects such as cracks, folds, ears, scars, delamination, and inclusions on the surface.

A. The Occurrence and Prevention of Crack Defects

Features: On the surface of the billet or steel, there are hair-like fine lines of different depths and scattered, which are generally unevenly arranged along the rolling direction.

Causes: subcutaneous bubbles, surface pores, non-metallic inclusions, uneven heating temperature, low steel temperature, or improper cooling after rolling (such as high-quality carbon structural steel), etc.

Preventive measures: steelmaking should do a good job of smelting and degassing molten steel, lower the tapping temperature, adopt protective casting to avoid secondary oxidation; steel rolling should reasonably control the furnace temperature and cooling rate.

B. Folding

Features: The surface of the steel is locally long or continuous, which is similar to cracks along the rolling direction. Generally linear.

Cause: The semi-finished rolled piece has ears, severe scratches, or the wrong roll of the rolled piece. When the rolled piece is re-rolled, the corners cannot be extended.

Preventive measures: Reasonably control the size of the semi-finished products. During the production process, wooden rods should be used to check whether there are ears and misaligned rolls on both sides of the rolling gap; pay attention to the operating conditions of the rolling.

C. Ears

Features: Overfilling of both sides or one side of the steel roll gap along the rolling direction causes local or continuous protrusions.

Causes: large incoming materials for the front hole of the finished product; biased and loose imported guides, and uneven rolling of the rolled piece; axial movement of the roll; uneven heating or too low temperature; and abrasion of the finished product pass produces stepped bumps.

Preventive measures: reasonably control the temperature of the heating furnace and the size of the semi-finished products; strictly adjust the guide and guard device; improve the pre-installation accuracy of the rolling mill; timing and quantitative reverse pass.

D. Scarring

Features: The surface of the steel is lumpy or scaly like “tongue-shaped” or “nail-shaped” scars of varying sizes, uneven thickness, and irregular shapes. Closed or not closed; rooted or unrooted. There is usually an iron oxide scale under the scar. Raised scars are also known as warped skins.

Causes: The billet has defects such as scarring, heavy skin, inclusions; semi-finished products have local bumps; pass cuts or trachoma; pass nicks or weld scars; rolling pieces slip in the pass; outside metal rolling Into the surface of the rolled piece; the semi-finished rolled piece is scratched by external objects.

Preventive measures: unqualified billets are not allowed to enter the furnace; when the pass pattern is notched or welded, the shape and height of the cut, weld mark should be smooth and smooth; strengthen the quality inspection of the roll; reasonable pass design; low temperature, blackhead steel rolling is strictly prohibited; often Check the wear and tear of the pass and invert the pass in time; the rolling piece transportation equipment and operating place should be tidy and smooth.

E. Scratches (Scratches, Abrasions)

Features: There are partial or intermittent groove marks on the surface of the steel, which are generally straight or arc-shaped.

Causes: improper installation of import and export guides and guards, or scratches on the transportation equipment of rolled parts; unfavorable de-grooving of rolled parts.

Preventive measures: correct processing, installation, and use of import and export guidance and guarding facilities; rolling parts transportation equipment and operation sites should be tidy and smooth.

F. Partial Periodic or Irregular Defects

Features: There are partial periodic or irregular concave defects on the surface of the steel.

Causes: the rolled pass has bumps or adhered iron scale; the surface of the steel does not fall off without root scars; foreign metal objects are substituted into the pass and formed after rolling off.

Preventive measures: the cooling water of the pass type should be clean and the water quantity should be sufficient; the quality of the billet should be qualified; the production environment should be free of debris.