Difference Between Push-steel Reheating Furnace and Walking Beam Reheating Furnace

Push-type continuous reheating furnace relies on the pusher to complete the task of conveying material in the furnace.

The billet slides on the bottom of the reheating furnace or on a slide supported by a water-cooled tube. In the latter case, the billet can be heated on both sides. Bottom water pipes are usually coated with insulation materials to reduce heat loss. In order to reduce the “black mark” on the lower part of the billet caused by the water-cooled sliding track, the “hot sliding track” which insulates the billet from the water pipe has been adopted in recent years. Some small continuous reheating furnaces use water-free sliding tracks made of special ceramic materials, which are supported on the base wall built by refractory materials. This kind of furnace is called a “water-free furnace”.

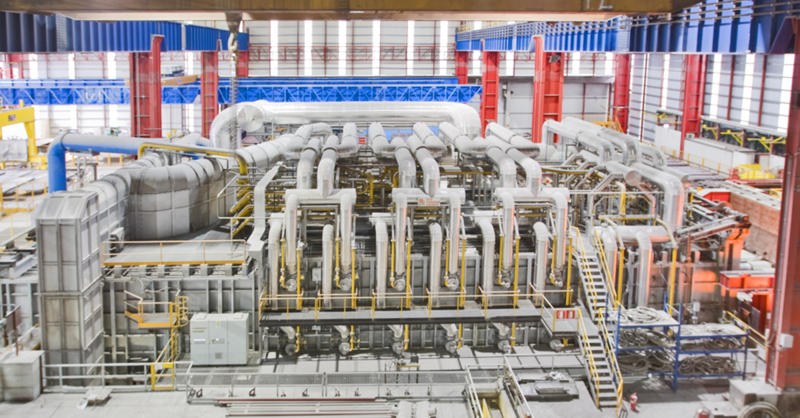

Walking type continuous reheating furnace transfers billet step by step to forward continuous reheating furnace by the action of rising, advancing, descending and retreating of furnace bottom or water-cooled metal beam.

The reheating furnace has a fixed bottom and a walking beam, or a fixed beam and a walking beam. The former is called the walking bottom reheating furnace, and the latter is called the walking beam reheating furnace. Walking beam of reheating furnace for steel rolling usually consists of a water-cooled pipe. Walking beam reheating furnace can heat billet on both sides. Since the 1970s, walking beam reheating furnace has been widely used because of the large-scale rolling mill. Compared with push-steel furnace, its advantages are: flexible material transportation, if necessary, all the burden can be discharged out of the furnace; the billet can be switched apart on the bottom or beam of the furnace, which can be heated more quickly and evenly; the failure of arch steel and sticking steel of push-steel furnace is completely eliminated, so that the length of the furnace is not limited by these factors.