Compared with the hot roll, the cold roll only rolls the cold-rolled piece, which is usually cast after smelting and often needs to be forged. With the development of casting technology, the cold roll is forged. It is being implemented continuously. The cold roll has a cold rolling work roll, an intermediate roll, and a support roll, the work roll is in direct contact with the rolling piece, the intermediate roll is only in contact with the work roll, and the support roll is in contact with the work roll and also in contact with the intermediate roll. Since cold rolling is cold rolling and the working conditions are bad, the quality of the cold rolling rolls is very strict. The cold-rolling rolls usually require surface quenching and the hardness is HS45-105.

Driven by the technology of pulling and roll manufacturing in the cold rolling industry, the requirements for increasing the wear resistance, roughness retention, hardness uniformity and anti-accident of cold rolls are increasing, with the aim of achieving free rolling. , rolling high-grade plates, reducing roll consumption and so on. Driven by these requirements, roll manufacturers are constantly striving to improve and innovate roll manufacturing technology. The specific performance is:

- Forging steel roll alloy composition continues to increase: 5%Cr, 8%Cr, 86CrMoV, semi-high-speed steel, high-speed steel and other high-alloy steel applications on cold rolls is a trend, while the roll material will maintain a variety of To meet the needs of different rolling conditions.

- Application of new roll blank composite manufacturing technology: In order to meet the requirements of high wear resistance of the roll surface and high comprehensive mechanical properties of the core, manufacturers have been exploring new surface composite technology such as electroslag casting, CPC, Osprey and so on in roll blank preparation. Use on.

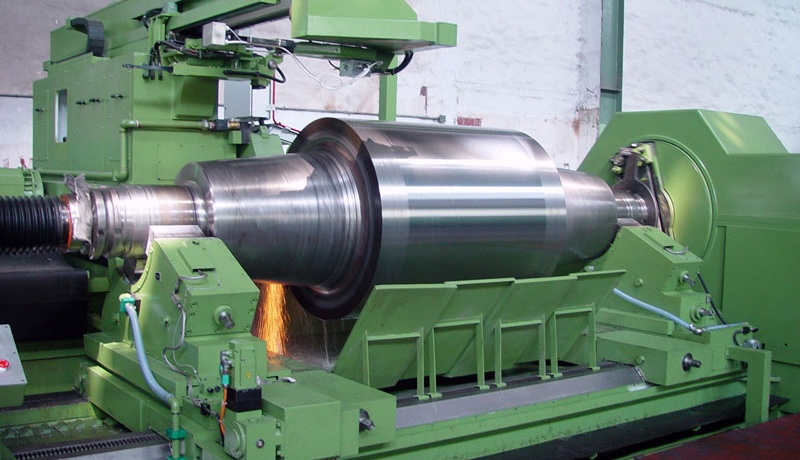

- Application of new roll heat treatment and processing technology: the application of large-scale CNC machine tools, the use of computer-controlled heating furnaces and quenching equipment can increase the manufacturing precision and surface uniformity of the rolls and meet the needs of high-end mills.