Different Properties of 2 Hi Rolling Mill and 4 Hi Rolling Mill

Many friends don’t know what a 4 Hi Rolling Mill is. In fact, the 4 hi rolling mill is a combination of two working rolls and two supporting rolls. It is not only the drive mechanism for the backup roll, but also the work roll driven equipment. The specific choice is to be selected according to the requirements of the customer, and it is also determined according to the actual use.

Difference Between a 2 Hi Rolling Mill and a 4 Hi Rolling Mill

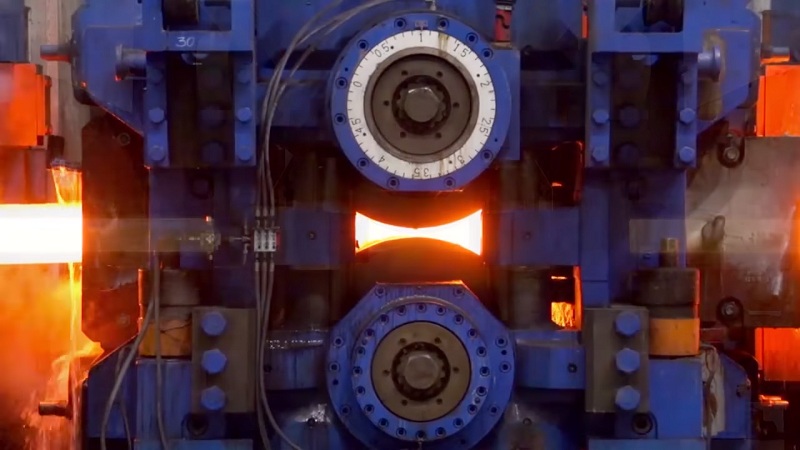

In the 2 hi rolling mills, the entire roll diameter is relatively large, and the area of contact with the tie pieces is also very large, so the overall rolling force is relatively large, so the material for rolling is There are certain requirements in the selection and thickness, so as to effectively avoid many unnecessary problems during the whole rolling process. The 4 hi rolling mill also has an increase in the roll train, so the roll diameter of the work can be much smaller, and the corresponding rolling force is much smaller. It is more suitable for rolling thinner materials, then the whole rolling The thickness and range of the system will be broader.

The above content focuses on the different properties of the rolling mills of different rolls. When choosing a rolling mill, we must first understand the nature of its work, so the choice will be relatively simple.