What is slit rolling?

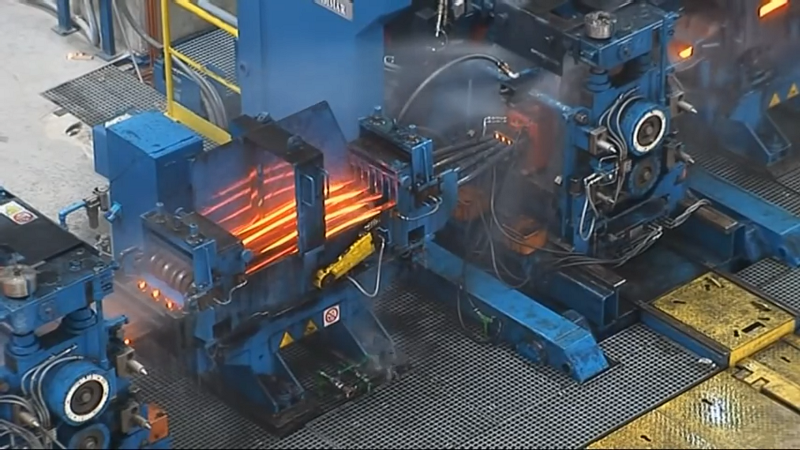

Slit rolling is a new technology widely studied and applied at home and abroad in the past two decades. The so-called slit rolling is a rolling process in which the billet is rolled into two or more parallel parts with the same cross-section shape through pass design, and then the billet is cut into two or more rolled parts with the same cross-section shape along the longitudinal direction by slitting equipment, and continuously rolled until the finished product is obtained.

According to the different structural characteristics of the slicing equipment, there are several different slicing methods at present.

1) The roll-cutting method uses the roll to slice the pass while deforming in the pass.

2) The slit wheel method first rolls the rolled piece into two or more parallel parts with the same shape through the pass and then cuts the rolled piece by the slit wheel installed at the exit side of the mill.

3) The disc shearing method first rolls the rolled piece into the shape ready for slicing and then cuts the rolled piece along the longitudinal direction by the disc shearing installed on the rolling mill line.

In addition to the above segmentation methods, flame segmentation is also used.