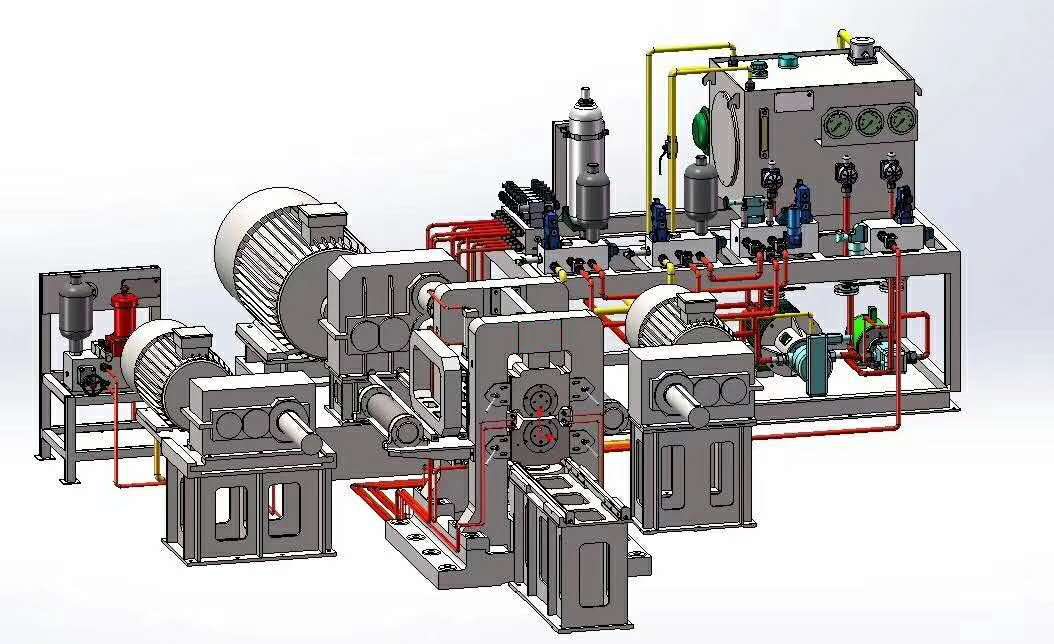

What are the Advantages of Multi-roll Mill Compared with Common Mill?

Compared with ordinary rolling mill equipment, when using multi-roll mill, will you enjoy many different advantages? For this problem, there should be a lot of friends are more concerned about it. Let’s analyze it together, hoping to deepen your understanding and better use it in future work.

In fact, there are many advantages of multi-roll mill, which are reflected in many aspects.

For example, the working roll of the equipment is supported by the backup roll as the medium. Therefore, in the direction of width, the roll is only subjected to a very small bending force, so we can choose the smaller diameter of the work roll. Secondly, by comparison, the stiffness and hardness of the equipment have been significantly improved, so in practical work, the processing accuracy of the product can be guaranteed.

Thirdly, the multi-roll mill has good adaptability. It can be used in different working situations, processing different materials, and obviously improving the rolling thinness. In addition, the equipment has little contact with the deformation zone, so that only a small total rolling force can be provided to meet the processing requirements, so energy consumption can be reduced.

Fourth, the use of this multi-roll mill can simplify the workflow and save time, which is equivalent to improving work efficiency. At the same time, it can save a lot of costs for users and increase economic benefits. Fifth, as the rolling tension increases, the shape and flatness of the strip can be significantly improved.

In addition, the volume of multi-roll mill has been reduced after structural improvement, which can save investment costs. At the same time, because of the direct pressing design, the equipment can also roll thicker raw materials, while effectively improving the safety of production work.