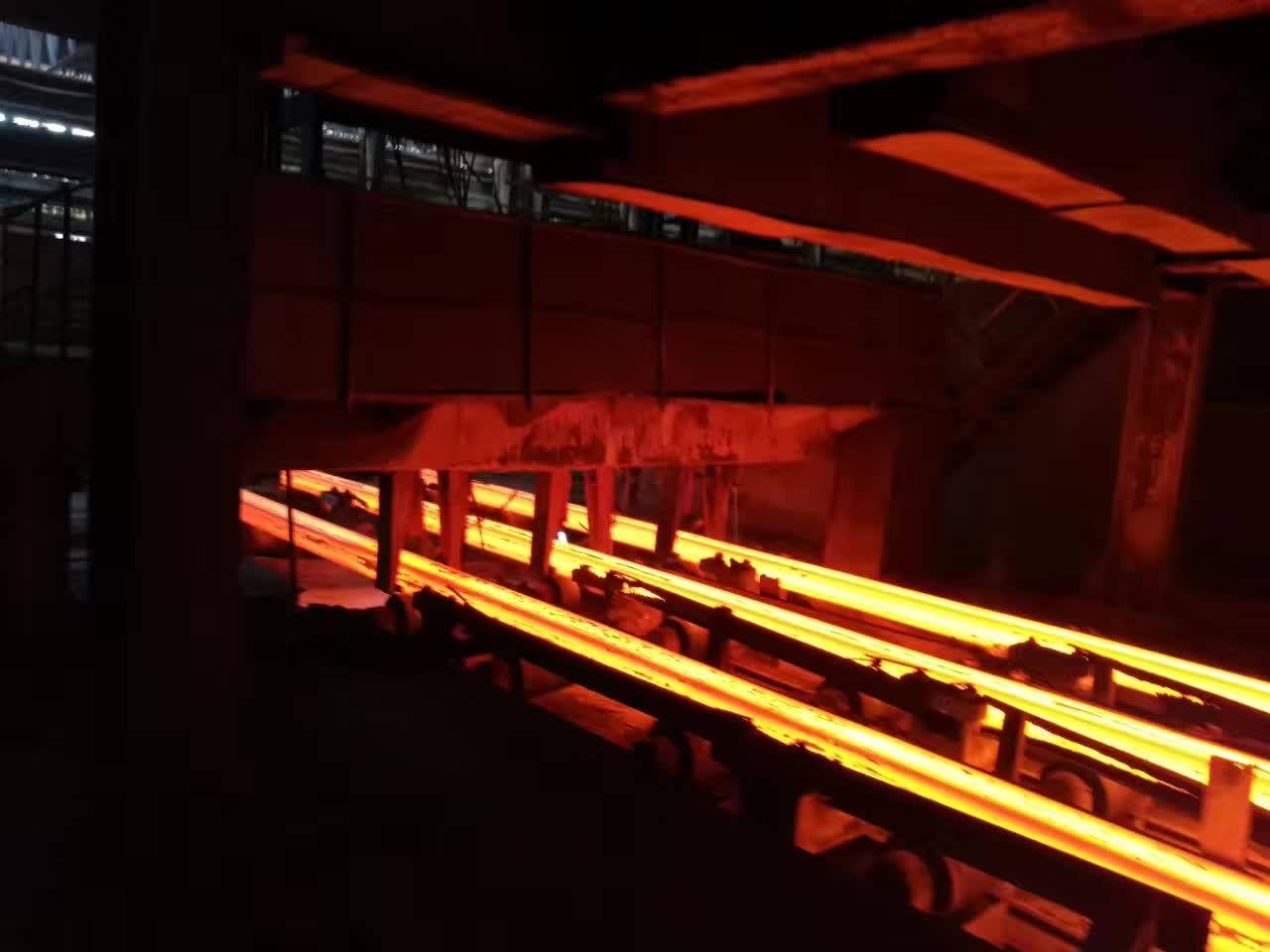

Arc Continuous Caster for Square and Round Billet

Main Technological Features of Arc Continuous Caster

The process characteristics of arc continuous caster for square and round billet mainly include the following aspects:

First, the arc radius of the arc continuous caster is 13 meters. Because the size of the arc radius can be directly matched with a variety of different steel grades for flexible production, the production scope of the square and round billet caster is greatly broadened. By improving the quality level of the internal billet, not only the control effect of the caster is effectively improved, but also the flexibility of production is enhanced, and the comprehensive benefit of the enterprise is promoted.

Secondly, square billet and round billet can be produced together. Due to the strong flexibility of the equipment and the need to adjust the technology for different customers in actual production, the characteristics of the square billet caster are highlighted. Due to the flexible exchange, not only the production radius of the round billet can be improved, but also the production of the square billet can be carried out, so that one machine can be used for multiple purposes, greatly expanding the scope of use, So as to save production and procurement costs for enterprises.

Third, automatic protection technology. Due to the automatic equipment added to the billet caster, the distribution uniformity of mold flux can be achieved by effectively controlling the adding speed of mold flux. In addition, the application scope of automatic protection technology also includes improving the lubrication conditions inside the mold and promoting the overall efficiency of production, so as to reduce the production risk and improve the overall profit.

Fourth, automatic mixing technology. The inner part of the square and round billet arc caster is equipped with a built-in hollow crystallization electromagnetic stirrer to realize the synchronous production of the surface and internal structure of the billet, thus greatly improving the internal quality of the billet. The application principle of automatic stirring technology mainly relies on electromagnetic stirring, so the energy consumption is reduced. Compared with the traditional use mode of the continuous caster, the electromagnetic stirring at the end of secondary cooling can also expand the axial crystal rate of the billet, which has a certain role in improving the loose environment inside the billet and enhancing the effect of central segregation of billet.

Process Parameters of Billet Caster

As an advanced continuous caster, the square billet caster belongs to the full arc continuous caster equipment type. At the same time, the arc radius is 13 meters, and the metallurgical length can reach as much as 28 meters. In addition, due to the flow spacing of 1200mm, the casting process quality control level of the whole equipment is relatively high. According to different process requirements, the adjustable range is also large. The pulling speed is 0.5 ~ 3.5m/min. The machinable section of the square billet and the round billet is basically 200mm, and the annual production capacity is higher no less than 1.5 million tons. At the same time, the metal recovery rate is effectively improved through the overall design of the equipment 10%.