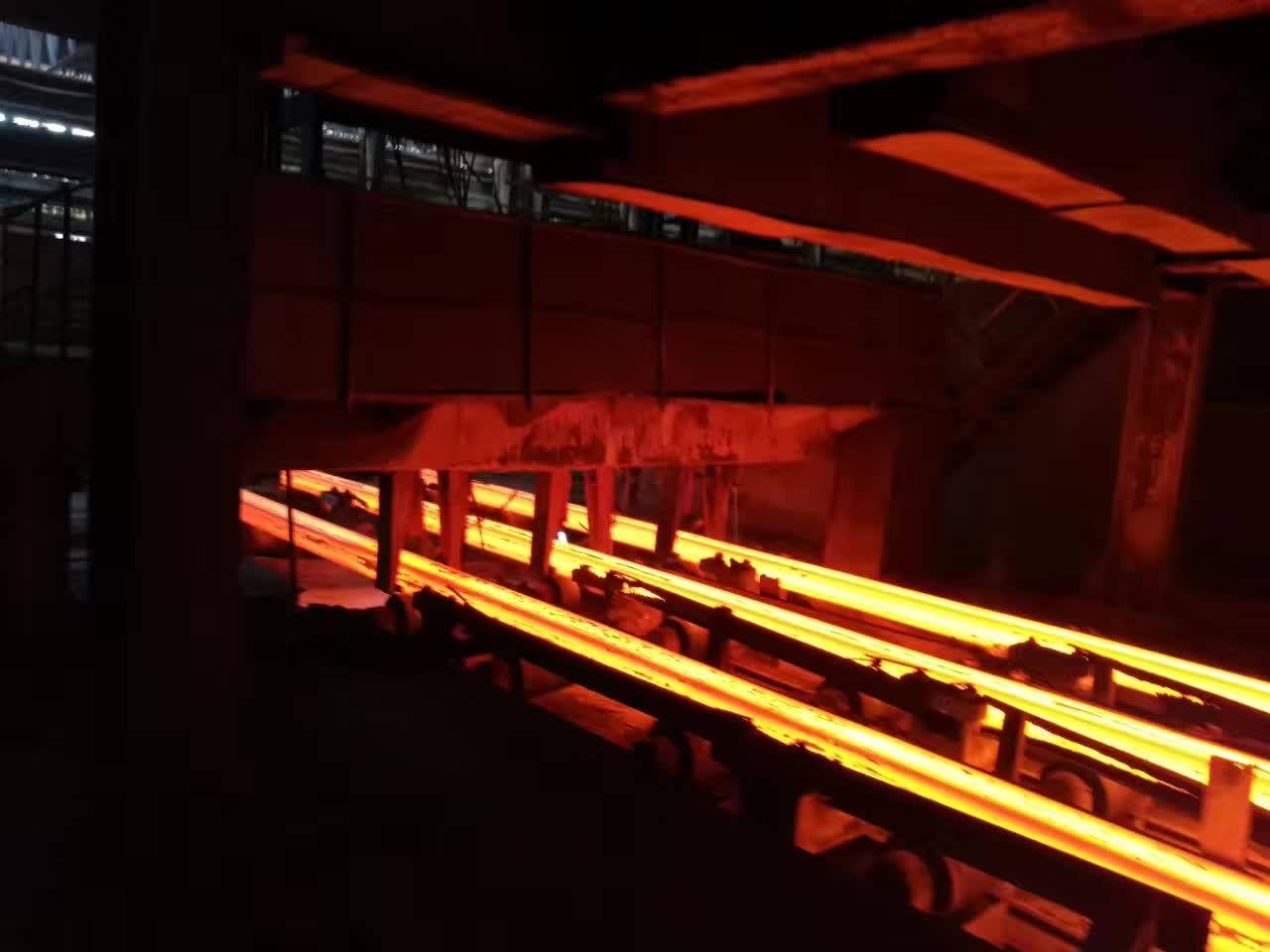

Roulette continue à arc pour billettes carrées et rondes

Principales caractéristiques technologiques de la roulette continue à arc

Les caractéristiques du processus de la roulette continue à arc pour billettes carrées et rondes comprennent principalement les aspects suivants:

D'abord, le rayon de l'arc de la roulette continue à arc est 13 mètres. Parce que la taille du rayon de l'arc peut être directement adaptée à une variété de nuances d'acier différentes pour une production flexible, la portée de production de la roulette de billettes carrées et rondes est considérablement élargie. En améliorant le niveau de qualité de la billette interne, non seulement l'effet de contrôle de la roulette est efficacement amélioré, mais aussi la flexibilité de la production est améliorée, et le bénéfice global de l'entreprise est promu.

Deuxièmement, la billette carrée et la billette ronde peuvent être produites ensemble. En raison de la grande flexibilité de l'équipement et de la nécessité d'adapter la technologie aux différents clients dans la production réelle, les caractéristiques de la roulette à billettes carrées sont mises en évidence. Grâce à l'échange flexible, non seulement le rayon de production de la billette ronde peut être amélioré, mais aussi la production de la billette carrée peut être réalisée, afin qu'une machine puisse être utilisée à des fins multiples, élargissant considérablement le champ d'utilisation, Afin d'économiser les coûts de production et d'approvisionnement pour les entreprises.

Troisième, technologie de protection automatique. Grâce à l'équipement automatique ajouté à la roulette de billettes, l'uniformité de distribution du flux de moule peut être obtenue en contrôlant efficacement la vitesse d'ajout du flux de moule. En outre, le champ d'application de la technologie de protection automatique comprend également l'amélioration des conditions de lubrification à l'intérieur du moule et la promotion de l'efficacité globale de la production, afin de réduire le risque de production et d'améliorer le profit global.

Quatrième, technologie de mélange automatique. La partie intérieure de la roulette à arc pour billettes carrées et rondes est équipée d'un agitateur électromagnétique à cristallisation creuse intégré pour réaliser la production synchrone de la surface et de la structure interne de la billette., améliorant ainsi considérablement la qualité interne de la billette. Le principe d'application de la technologie d'agitation automatique repose principalement sur l'agitation électromagnétique, donc la consommation d'énergie est réduite. Par rapport au mode d'utilisation traditionnel de la roulette continue, l'agitation électromagnétique à la fin du refroidissement secondaire peut également augmenter le taux de cristallisation axiale de la billette, qui joue un certain rôle dans l'amélioration de l'environnement meuble à l'intérieur de la billette et dans le renforcement de l'effet de ségrégation centrale de la billette.

Paramètres de processus de la roulette de billettes

En tant que roulette continue avancée, la roulette à billettes carrées appartient au roulette continue à arc complet type d'équipement. En même temps, le rayon de l'arc est 13 mètres, et la longueur métallurgique peut atteindre jusqu'à 28 mètres. En outre, grâce à la distance d'écoulement de 1200 mm, le niveau de contrôle de qualité du processus de coulée de l'ensemble de l'équipement est relativement élevé. Selon différentes exigences de processus, la plage de réglage est également large. La vitesse de traction est 0.5 ~ 3,5 m/min. La section usinable de la billette carrée et de la billette ronde est essentiellement de 200 mm., et la capacité de production annuelle est supérieure à pas moins de 1.5 millions de tonnes. En même temps, le taux de récupération des métaux est efficacement amélioré grâce à la conception globale de l'équipement 10%.