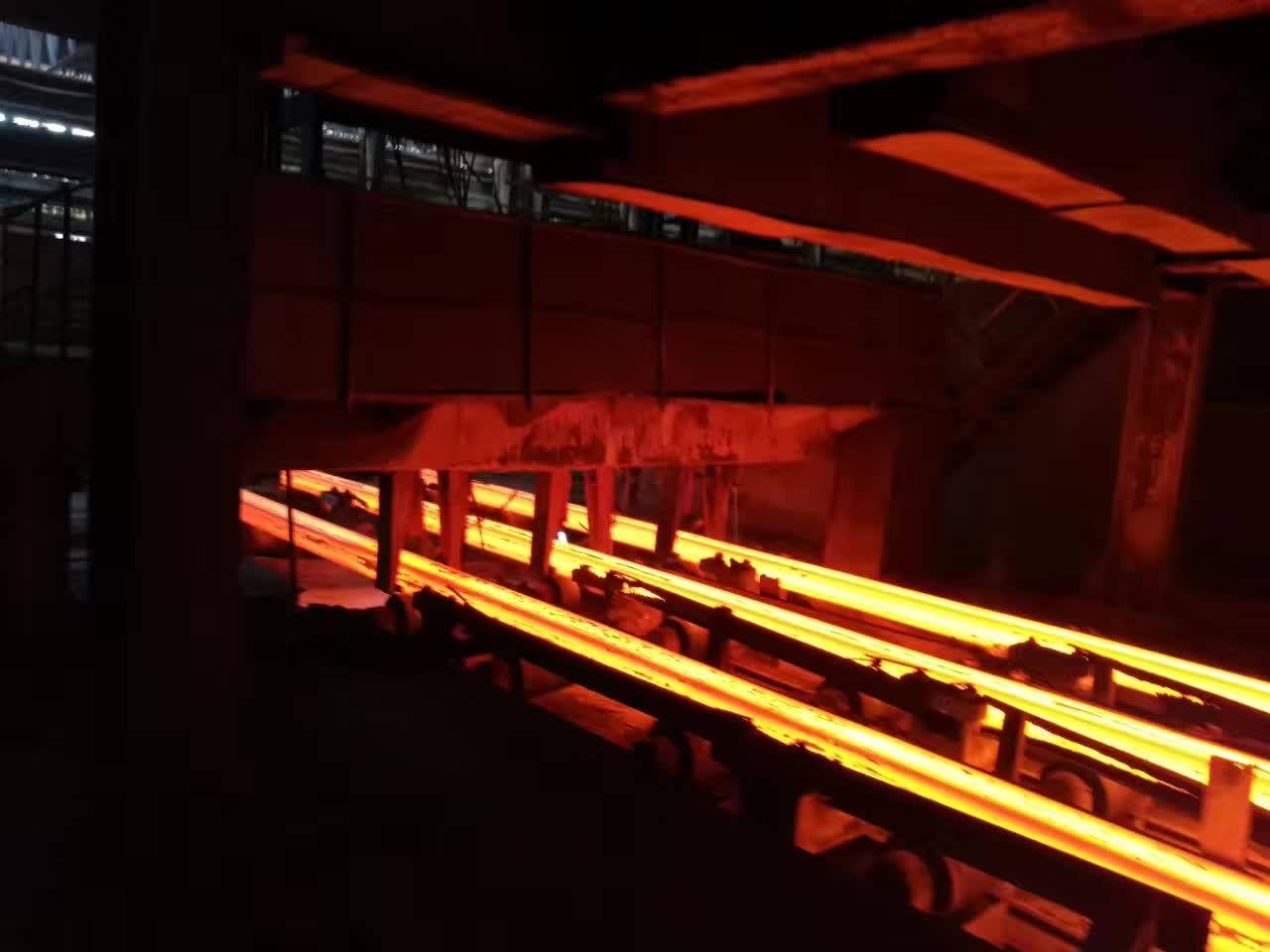

МНЛЗ для производства квадратных и круглых заготовок

Основные технологические особенности МНЛЗ

Технологические характеристики дуговой МНЛЗ для квадратных и круглых заготовок в основном включают следующие аспекты::

Первый, Радиус дуги МНЛЗ составляет 13 метры. Потому что размер радиуса дуги можно напрямую подобрать для различных марок стали, что обеспечивает гибкость производства., объем производства машин для разливки квадратных и круглых заготовок значительно расширен.. За счет повышения уровня качества внутренней заготовки, эффективно улучшается не только эффект контроля заклинателя, но также повышается гибкость производства, и всесторонняя выгода предприятия повышается.

Во-вторых, квадратную и круглую заготовку можно производить вместе. Из-за высокой гибкости оборудования и необходимости адаптировать технологию для разных клиентов в реальном производстве., выделены характеристики МНЛЗ квадратных заготовок. Благодаря гибкому обмену, можно улучшить не только радиус производства круглой заготовки, но также может быть осуществлено производство квадратных заготовок, чтобы одну машину можно было использовать для нескольких целей, значительно расширяет сферу использования, Чтобы сэкономить затраты на производство и закупки для предприятий.

Третий, технология автоматической защиты. За счет автоматического оборудования, добавленного к МНЛЗ., Равномерность распределения флюса в пресс-форме может быть достигнута за счет эффективного контроля скорости добавления флюса в пресс-форму.. Кроме того, Область применения технологии автоматической защиты также включает улучшение условий смазки внутри формы и повышение общей эффективности производства., с тем, чтобы уменьшить производственный риск и улучшить общую прибыль.

Четвертый, технология автоматического смешивания. Внутренняя часть дуговой МНЛЗ для квадратных и круглых заготовок оснащена встроенной полой электромагнитной мешалкой для кристаллизации, обеспечивающей синхронное производство поверхности и внутренней структуры заготовки., тем самым значительно улучшая внутреннее качество заготовки. Принцип применения технологии автоматического перемешивания в основном основан на электромагнитном перемешивании., поэтому потребление энергии снижается. По сравнению с традиционным режимом использования МНЛЗ, Электромагнитное перемешивание в конце вторичного охлаждения также может увеличить осевую скорость кристаллизации заготовки., что играет определенную роль в улучшении рыхлой среды внутри заготовки и усилении эффекта центральной сегрегации заготовки..

Параметры процесса МНЛЗ

В качестве усовершенствованной машины непрерывного литья заготовок, машина для разливки квадратных заготовок относится к МНЛЗ с полной дугой тип оборудования. В то же время, радиус дуги 13 метры, а металлургическая длина может достигать целых 28 метры. Кроме того, благодаря пролету 1200мм, уровень контроля качества процесса литья всего оборудования относительно высок. В соответствии с различными требованиями к процессу, диапазон регулировки также большой. Скорость тяги 0.5 ~ 3,5 м/мин. Обрабатываемое сечение квадратной и круглой заготовок обычно составляет 200 мм., и годовая производственная мощность выше не менее чем 1.5 миллион тонн. В то же время, степень извлечения металла эффективно повышается за счет общей конструкции оборудования 10%.