Sendzimir Mill Features

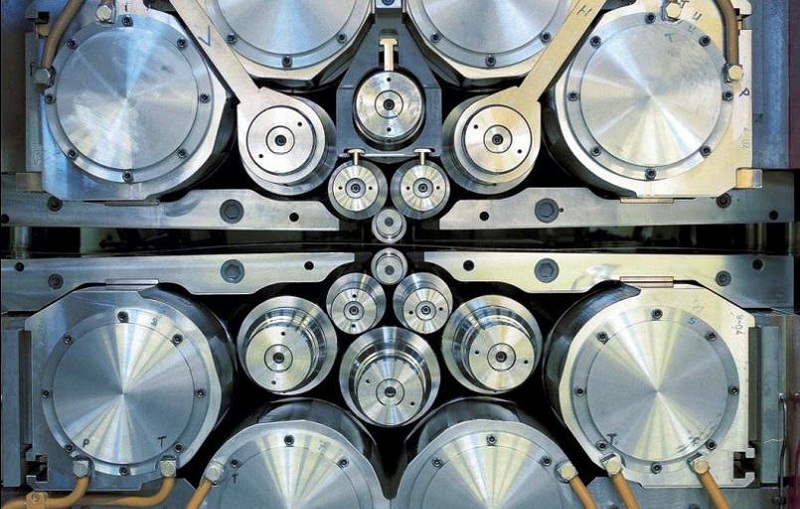

The Sendzimir mill arch is integrally cast and pre-stressed, and a circular arc track is provided in the arch to secure the backup roll. All the intermediate rolls are fixed on the arch by the suspension hydraulic cylinders on the transmission side and the operation side, and the suspension force is set according to the weight of the roller body.

The main advantages of the Sendzimir 20-hi rolling mill:

1) The work roll has a small diameter, and most of the current rolling mills use a work roll of Φ63.5;

2) The roll system is stable, and the roller system instability problem has not occurred for many years;

3) The rigidity is large, generally reaching 4440~4900kN/mm, which is beneficial to increase the thickness precision;

4) The upper limit of rolling pressure is large, generally reaching 7800~8000kN, and the amount of pass reduction is large;

5) Because the outer support roll adopts bearings, the convexity adjustment is flexible and convenient;

6) An intermediate roll axial movement can be realized, which is beneficial to the strip-type control of the strip side;

7) Flexible adjustment of the height of the rolling line can be achieved by adjusting the F and G rolls;

8) Rolling cooling oil is supplied through the guide plate for oil cooling, and the lubrication and lubrication effect is good;

9) There are no moving parts in the frame except for the roll and the belt guide, which is easy to operate and maintain, and reliable in operation;

The main disadvantages of Sendzimir Mill 20-hi cold rolling mill:

1) The small opening is not conducive to wearing and rolling. Can not achieve automatic roll change, long rollover time;

2) The roll can be used in a small range, the rolling thickness specification needs to be used together, the roll reserve is large, and the roll management and use cost are high;

3) Adjusted by rack and eccentric ring, the response is slow and the control precision is low;

4) There are few plate type control methods and the plate type control ability is poor. Due to the overall structure of the rack, direct tilt control cannot be achieved.

When adjustment, the two bearings are affected at the same time, and the transmission force of the support roll, the second intermediate roll, and the first intermediate roll is reduced, and the control capability is greatly reduced. Plate type adjustment is difficult to quantify, especially after the actual rolling plate type appears 1/4 wave, it cannot be completely eliminated. The first intermediate roller has a certain taper, and the first intermediate roll is axially moved by the action of a push-pull hydraulic cylinder. Considering the push-pull force state, the plate type control only participates when the rolling speed reaches 100 m/min. Due to the limitation of the moving speed, when the rolling speed of the head and tail is less than 100m/min, the plate type control ability is greatly affected, and the main operation tool is required to have high operation skills.