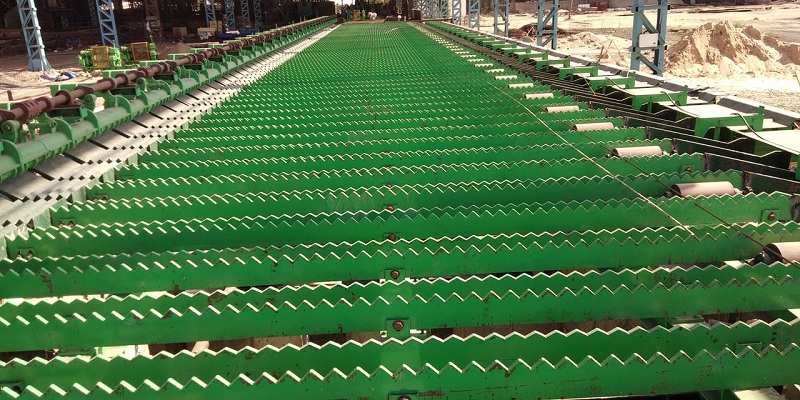

The bar rolling mill cooling bed is one of the indispensable auxiliary equipment for the small and medium bar rolling mill workshop. Its function is to cut the bar after being rolled by the flying shear into multiple lengths of the rolling mill, transport it and discharge it to the cooling rack to cool it, and reduce its temperature from 900 °C to 100 ~ 300 °C, then by the cooling bed. The material collection device collects them into a group and sends them to the output roller, and then sends them to the cold shear to cut into finished products by the output roller. The design quality and installation accuracy of the bar mill step-type cooling bed directly determine the final quality of the product.

What are the main advantages of the step-type cooling bed?

1. When the step-type cooling bed transports steel, there is no friction between the steel and the bracket, so the bottom surface of the steel will not be scratched.

2. The cooling area of the cooling bed can be adapted to the cooling requirements of steels of various widths and can be fully utilized.

3. The cooling bed plane is a mechanical plane with a well-arranged structure. Therefore, the flatness of the steel after cooling is good, which is very advantageous for the shearing of the steel.

4. Whether it is a fixed beam of a step-type cooling bed or a movable beam, there are a large number of uniformly dense holes on the contact surface with the steel, through which cold air can cool the lower surface of the steel; steel and fixed The contact time of the beam and the movable beam is the same, so the steel not only cools quickly but also the cooling is relatively uniform, so that the steel has a relatively uniform structure and performance.

5. Steel can be moved forward or backward on a cooling bed to facilitate production operations and adjustments.